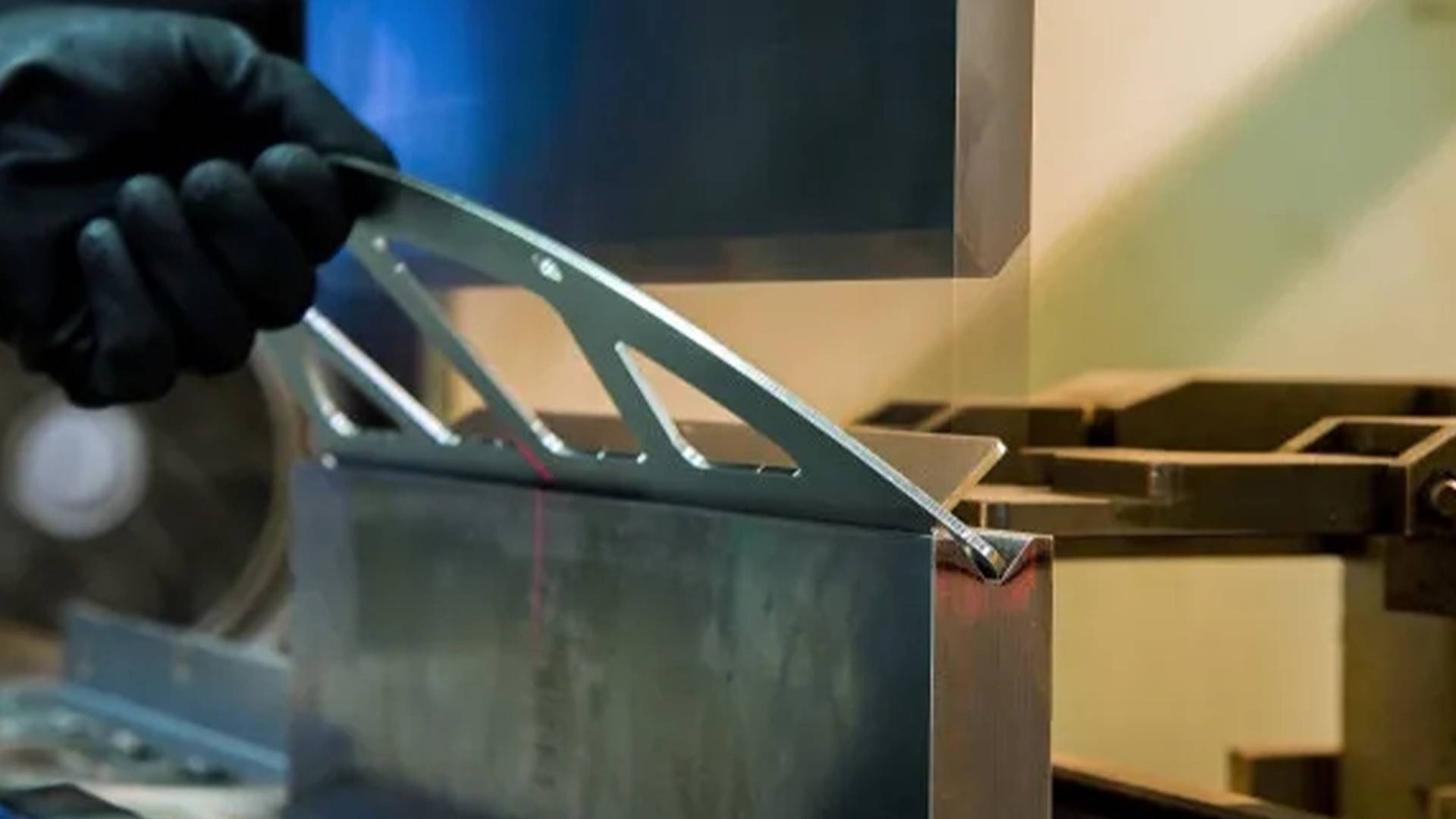

Metal forming tool

In the field of metal processing, bending machines play a vital role. Like a skilled craftsman, they shape ordinary metal sheets into various complex shapes and are widely used in industries such as construction, automobiles, and home appliances. Working principle of bending machine

Working principle of bending machine

The bending machine is mainly driven by hydraulic or mechanical means, and uses the upper and lower dies to apply pressure to the metal sheet to cause it to undergo plastic deformation, thereby achieving the purpose of bending. According to the different bending methods, the bending machine can be divided into:

The following factors need to be considered when choosing a suitable bending machine:

With the advancement of Industry 4.0, bending machines are also developing towards intelligence and automation. In the future, bending machines will be more intelligent and can realize functions such as automatic programming, automatic mold change, and automatic detection, further improving production efficiency and processing accuracy.

In conclusion

As an important equipment for metal processing, the bending machine has an increasingly wide range of applications. Understanding the working principle, advantages and selection of suitable bending machines is of great significance for improving production efficiency and product quality. I believe that with the continuous development of technology, bending machines will play a more important role in the future.

l\'équipe professionnelle au service !